The hand drill is a tool that was very popular before the advent of power tools. Every self-respecting master had at least one such drill in his arsenal, which was simply an indispensable assistant. But such a tool has a significant drawback - the need to use physical force. Today, such tools have been replaced by more rational ones - electric drills and cordless screwdrivers. New tools have appeared, but what to do with old hand drills? If you have a USSR-era hand drill lying around in your garage, do not rush to dispose of it. You can make some useful things out of this tool. This material will explore several ideas.

The hand drill was created to drill holes in various types of materials: wood, plastic and metal. The operating principle is based on a pair of gears of different diameters, which allows you to increase the rotation speed, thereby making the tool quite suitable for drilling. It is thanks to the gear mechanism that the tool has become widespread and is used even today.

Interest in the use of a hand drill has decreased since the invention of electric drills, but they still resort to using this tool in extreme cases when there is no electricity and it is necessary to urgently drill a hole. Let's not delve into the details of this tool, but rather find out what can be made from an old hand drill?

Option 1

If you are wondering what can be done from an old hand drill, then you are on the right track. Don’t rush to throw it away, as it can be used to make an excellent attachment for a screwdriver. Ready product allows you to unscrew and tighten different kinds fasteners in hard-to-reach places using a screwdriver. Let's look at how to make such a device in more detail.

The advantages of such an attachment for a screwdriver

The advantages of this console include the following points:

- Increases the torque of a screwdriver by approximately 6-7 times.

- Possibility of screwing and unscrewing bolts and nuts in hard-to-reach places.

- Ease of manufacture of the device.

- Does not require any additional capital investment.

- Expanded capabilities when working with a screwdriver.

This homemade attachment will definitely come in handy around the house, as well as when carrying out car repair work.

What to make from an old hand drill: option 2

You can also use a hand drill to make a very convenient wrench, something like a ratchet. All you need for this is two gears and some additional details. The result will be a tool of the type shown in the photo below.

Details of its production can be seen in the video:

In conclusion, it should be noted that this useful thing, like a hand drill, there are still many ideas for use.

When performing carpentry and plumbing work, an appropriate tool is usually used, designed to perform specific tasks. However, there are situations when it is much more convenient and easier to use special machines. They allow you to optimize the process and save time during the same type of work. Therefore, questions about how to make a drilling machine from a drill very often arise among modern craftsmen.

Necessity or luxury

First of all, it is worth saying that using such a device is very convenient when making holes in small horizontal planes. It almost completely eliminates the drill from backlash, which inevitably occurs when handmade. Even a small drilling machine from a drill significantly increases the accuracy of the hole made, minimally reducing the error. Also, such equipment greatly saves time and effort if frequent use or monotonous work is required.

Almost all enterprises where plumbing work is performed are equipped with such units. The fact is that studies conducted in the field of occupational safety have shown an increase in productivity and quality when using them. Some even purchase a magnetic drilling machine to optimize their production. large planes without the use of expensive equipment.

Why drill?

Currently, there are a lot of designs for creating such equipment at home. However, most experts recommend making a drilling machine from a drill. This is due to the fact that this tool already completely contains all the necessary components and assemblies, and they do not have to be purchased separately. In this case, the fixation on the structure is carried out so that you can easily remove the drill for independent work. As a result, we do not lose a tool that we can use ourselves.

In order to create a drilling machine from a drill with your own hands, you need to purchase the tool itself. It is selected in accordance with the parameters that the finished device will have to have. At the same time, experts advise paying attention to products that have their own slight play. Otherwise, the advisability of using it for work is called into question. You may also need:

- Guides. They use systems used in furniture production, or metal strips.

- Bed. Most often it is made of a metal plate or a wooden box onto which magnets or ballast are attached for weighting.

- Fasteners When making a drilling machine from a drill with your own hands, you immediately select couplings or clamps suitable for fixing a specific tool.

- Wood or metal structures - depending on what material is to be processed.

- The spring required to implement the reverse motion.

- If a drilling machine with a magnetic sole is created, then the magnets themselves will be needed.

Tool

IN in this case the selection of the tool used depends on the material for creating the frame. However, it is immediately worth noting that a corner for measuring the connection of elements at 90 degrees will be necessary in any case. Even a mini-drilling machine requires great precision during its manufacture, since this will subsequently affect the quality of the holes produced.

First of all, you need to decide on the design of the final product and the material for its manufacture. However, there is no need to come up with too complex technical solutions or expensive units. A typical drawing of a drill press from a drill is quite simple. It involves creating a strong and stable frame on which a vertical tripod with a movable carriage is mounted. Taking this into account, special attention should be paid to the implementation of moving the drill in the vertical plane, although the use of ready-made guides greatly simplifies this process. If you use the stand of a microscope, photo enlarger or press as a frame, then the drawing will be based on their base, and the entire manufacturing process is greatly simplified.

Stand and tripod

Even a mini drill press needs a stable base. It should not only hold the entire structure, but can be equipped with various elements for fixing tools or other devices. When thinking about the design of a drilling machine, it is worth listening to the advice of experts. Many craftsmen recommend creating these devices from wood. Therefore, for the bed they use wooden frame in the form of a small box. There are seats on it for installing a vice or other structures. If the product is planned to be used on large surfaces, then the frame is made of a solid plate with a hole for a drill. This way you can implement the principle of drilling through.

Almost any drilling machine device involves installing a vertical tripod at an angle of 90 degrees to the bed. Therefore, it is very important to use an accurate measuring tool in your work. You also need to securely fix the tripod using additional fastenings in the form of corners.

If the work involves drilling holes at a certain angle, then you can make certain devices in advance that will be mounted on the frame. Most often, in such cases, ready-made ball vices with an adjustable angle of inclination are used.

Creating a Motion Mechanism

When making a homemade drilling machine from a drill, special attention must be paid to this stage. The fact is that the vertical stroke should be soft, without distortions, play or displacement. Taking this into account, professional craftsmen recommend using ready-made guides that can be taken from other devices. You can also use systems made to pull out drawers in cabinet furniture. They are quite reliable and can withstand heavy loads.

The guides are installed directly on the tripod or special strips attached to it. In this work, it is very important to use a measuring tool, since these elements must also be positioned at an angle of 90 degrees with respect to the frame and parallel to each other. Even small distortions or displacements should not be allowed.

The second part of the guides is fixed to a special carriage, where the drill itself will be installed. It is made of wood and adjusted to the dimensions of the original instrument. A small handle is also attached to the carriage, with which the operator will control the moving process.

To implement the return movement and facilitate control of the movement of the carriage, a spring is installed on the machine. One end of it is fixed at the top of the tripod, and the other is mounted on a movable mechanism. In this case, they immediately check the level of its tension, which, if necessary, can be changed by cutting the turns or stretching them. However, this adjustment is best done under load, which means it is performed only after fixing the drill on the carriage. Some craftsmen recommend making the spring removable so that it can be removed after work. This way it will not stretch and weaken.

Fixing the drill

Typically, instructions on how to make a drill press from a drill recommend creating special fastening systems that end up being very difficult to work with. However, if the tool is selected correctly, it can be fixed using ordinary plumbing clamps used to create connections between hoses and pipes. In this case, you will need to make certain changes to the shape of the carriage or even slightly adjust the drill body.

It is very important that the tool is clamped tightly and moves in the clamp. Therefore, even at the manufacturing stage of the carriage, they practically do not leave him free space, limiting structurally on all sides. In fact, the carriage itself is a kind of bed for the drill, in which it will sit very tightly. Additional elements are needed only for reliable fixation. This approach will greatly simplify the design and allow you to quickly remove the tool if necessary.

Taking into account the material presented above, we can conclude that a drilling machine from a drill can be made independently and without large financial costs. In this case, the final product will be maximally adapted to the performance of specific technical tasks and will be able to satisfy the relevant needs of the end user. However, it is worth considering the fact that factory designs usually have less error and are capable of performing precise work with minimal tolerance. Therefore, such devices are usually suitable for private use or in small workshops where high-precision holes are not required.

9 famous women who fell in love with women Showing interest not in opposite sex is not something unusual. You are unlikely to be able to surprise or shock anyone if you admit it.

15 Cancer Symptoms Women Most Often Ignore Many signs of cancer are similar to symptoms of other diseases or conditions, which is why they are often ignored. Pay attention to your body. If you notice.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don’t worry about the shape and length of their hair. It seems that youth is created for experiments with appearance and daring curls. However, already last.

What is it like to be a virgin at 30? I wonder what it’s like for women who didn’t have sex until almost middle age.

These 10 little things a man always notices in a woman Do you think your man doesn’t understand anything about female psychology? This is wrong. Not a single little thing can be hidden from the gaze of a partner who loves you. And here are 10 things.

Our ancestors slept differently than we do. What are we doing wrong? It's hard to believe, but scientists and many historians are inclined to believe that modern man sleeps completely differently than his ancient ancestors. Initially.

Do it yourself circular saw and other drill machines

Sometimes there is a need to cut a fairly hard board into several planks. You can’t do this kind of work manually, but buy a factory one circular saw for the sake of a single case it is unprofitable. There is a very simple solution - it is done small size circular saw from a regular drill.

Design

It is better to make the machine small in size so that it can be put on a shelf when its presence is no longer needed. Its design is extremely simple:

- base made of a thick board or piece of chipboard;

- working surface;

- racks;

- shaft with circular saw;

- electric drive in the form of a drill.

We make the base from a sheet of chipboard 30 mm thick; it is enough to cut out a piece measuring 300x250 mm. For desktop We choose a sheet of duralumin 4 mm thick - it is quite rigid and light, so as not to weigh down the entire structure. We make a hole in the right place for circular saw measuring approximately 160x10 mm.

The holder for the drill itself can be made independently - that’s all required dimensions and the drawings are available on the Internet, but a similar design for a shaft with a saw can be purchased in a store or at a clothing market. The bearing for the shaft must be selected dustproof- when the homemade machine is working, there will be a lot of small waste in the form of wood dust.

A circular saw from a drill is assembled according to the standard scheme: first, all parts are fixed to the base, then the work table is mounted and the drill is connected.

Security measures

When working on any machine, you must strictly follow the following rules:

- the place of upcoming work must be cleared of unnecessary materials and tools;

- workpieces are fed smoothly without jerking or distortion, so that the cutting tool does not jam;

- the plane of rotation of the circular saw must be limited from above by a special protective casing ;

- the machine must be kept clean and put away after each use;

- If the mini sawmill is not used for a long time, then lubricate all metal parts with machine oil.

This small machine can cut not only wooden boards. If you install special cutters on it, you can process parts made of brass and other non-ferrous metals, plastic or propylene.

Other homemade machines

Many users are interested in what else can be done using improvised tools from a drill with their own hands? There are many answers - home craftsmen are already making various homemade products from drills in garage workshops. A drill is a universal tool, so with a certain skill and imagination you can make whatever your heart desires.

- Sharpener. you just need to buy some emery in the form of a circle and make a special holder in which the drill is attached.

- Drillingmachine- there are special holders for vertical drilling or stands.

- Turningmachine small size for wood processing.

- Mini drill for various needs of the home handyman.

- To mow the grass around your garden without any problems, you can do it yourself drill trimmer .

- Grinder from a drill It’s done quickly, just buy specific attachments.

- Garage car repair technicians install original winches to replace engines based on old, very powerful tools.

- Gardeners make holes for planting young trees using homemade drill bit .

- When pouring the foundation for a utility room in the private sector, some users use homemade vibrator. made from a drill to quickly compact a concrete structure.

Original devices

You can continue the list of homemade products ad infinitum, but we’d better tell you in more detail about some homemade machines, which can be made from any drill model.

A drill made from a drill is not a fantasy, but a real and quite universal machine, assembled independently. The main thing is that you need to order from Chinese engineers (if you couldn’t find it in your city) flexible shaft from a standard medical unit. As a result, a drill appears in your arsenal, which can be used for engraving work or drill holes using special burs in small parts or structures that cannot be reached with a standard drill.

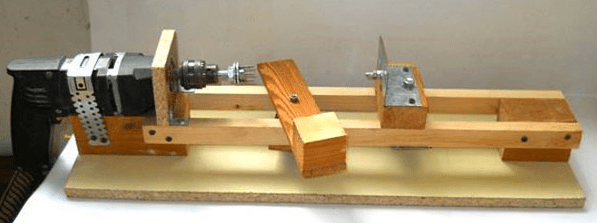

Lathe

A woodworking or lathe for home can easily be made using a drill. The tool must be secured with special clamps quite rigidly and inserted into a chuck of a special design holder with several sharp pins that keep the workpiece from turning. The center of the rear holder (headstock) and the clamp at the front of a homemade lathe should be located on the same axis. Precision is necessary to prevent runout as the workpiece rotates. After installing the part, tailstock It is firmly fixed with a special clamp.

The third element of the machine is handyman as wooden block, on which a chisel or other tool for processing the workpiece will rest.

Important! When working on a lathe, do not forget about safety, be sure to wear safety glasses, and the sleeves of clothing should fit tightly around your forearms.

Turning processing machine wooden blanks will work properly if the drill has a built-in electronic speed controller. By trial method you establish optimal mode rotation for efficient wood processing. Using such a woodworking device, you can make unique products for household needs: for example, a rolling pin or pestle with a mortar, a candlestick or a prefabricated candelabra.

An original winch based on an old but powerful drill will become an indispensable assistant in the household, especially for those users who live in own home and there is personal plot. Simple situation: in summer shower you decide to install a larger container, but raising it to such a height alone is problematic. Using a winch, this can be done in a few minutes. You just need to first calculate the weight of the container and the spindle speed.

According to garage craftsmen, a homemade winch easily lifts the engine from passenger car. Watch the video if you don't take my word for it:

Experts advise using homemade device, setting the drill to the most minimum speed. This design can move objects with different masses, because craftsmen even make winches based on an ordinary car starter.

How to make a drilling machine with your own hands

It is advisable to make a drilling machine with your own hands in situations where in a home workshop or garage there will be a need to drill holes in parts of various configurations, as well as those made of different materials. It should be noted that such a device makes it possible to obtain holes with sufficient high level quality.

One of the options for a homemade drilling machine

When you need a homemade drilling machine

In production or repair enterprises, where the drilling operation is considered the most common, it is used to perform it. special device, models of which may have different functionality. So, it can be a compact tabletop drilling machine, distinguished simplest design, or equipment equipped with several working spindles and numerical control.

Basic design elements of a homemade machine

For drilling holes in various materials, which is performed in a home workshop or garage, you can use home-made equipment. Naturally, for use at home you need a simple device that can be made from components and materials found in almost any garage or home workshop.

And in this article we will not leave unanswered the question of how to make a drilling machine at home, while spending a minimum of money. The drawings and experience of many craftsmen who have already walked this path will help us with this.

The need for such mini drilling equipment for metal, wood or plastic most often arises among those who are accustomed to independently performing various renovation work in your house or apartment. Also, quite often radio amateurs are puzzled by the construction of miniature drilling machines.

It would seem that a conventional drill can be used to perform such an operation, but such a tool is not always able to provide the required quality and accuracy of drilling operations. Homemade drilling machine. in addition to its compactness, it has another important quality: It can accommodate different types of drills.

Simple mini drilling machine for small jobs

Drilling machine from a conventional drill

To make a small but functional drilling machine for your home workshop, you do not need to purchase special materials and components. The design of such a convenient and useful desktop device contains the following components:

- the base, which is also called the bed;

- a mechanism that ensures rotation of the working tool (a conventional drill can be used as such a mechanism);

- device for providing supply;

- a vertical stand on which the rotation mechanism is fixed.

Diagram of a homemade machine from a drill

The stand on which the drill will be mounted can be made from a sheet of chipboard. This material is quite capable of supporting the weight of such a device. The bed of such a mini-machine should be more massive, since it protects the entire structure from vibrations, which can negatively affect both the quality and accuracy of the resulting hole, and the comfort of work.

As the material for the frame of such a drilling and adding machine, you can use a regular furniture board, the thickness of which is more than 2 cm. It is most convenient to use the base of an old photographic enlarger for this, slightly modifying its design. Sometimes an old microscope is used, but this is quite rare option, since such a unit will not be large enough and its use will be limited.

Drilling machine from a school microscope

The quality and accuracy that a homemade drilling machine will provide depends primarily on how correctly and reliably the connection of its base and vertical stand. Important elements Such a micro machine consists of two guides along which the block with the drill attached to it will move. Such guides are best made from two strips of steel, which must be securely screwed to the rack using screws.

When making the block, it is advisable to use steel clamps that will securely fix the drill on it. In addition, in order to avoid unwanted vibration processes when drilling, a thick rubber gasket must be installed at the junction of the block and the drill.

After this, you need to make a feed mechanism for such a mini machine, which should ensure the movement of the electric drill in the vertical direction. The manufacturing schemes for such a mechanism may be different, but it traditionally contains in its design a lever and a spring, which is attached at one end to the stand, and at the other to the block with the drill. This spring gives the feed mechanism greater rigidity.

A drilling machine from a drill, which is not planned to be removed from it, can be made more convenient to use if you disassemble the original switch of the drill and mount a separate button on the frame of the mini equipment. This button will always be at your fingertips and will allow you to quickly turn the device on and off. As you can see, it’s not at all difficult to make a drilling machine from a drill; all you need to do is read these instructions carefully or watch the training videos in this article.

An example of a drill machine in more detail

As an example, let's look in more detail at one of the options for a homemade drilling machine made from a drill. collected at home.

Do-it-yourself drilling machine from a drill

Manufacturing a machine using an asynchronous motor

The absence of an extra electric drill in the household is not a reason to abandon the idea of making a drilling machine with your own hands. Any electric motor can be used to drive the rotation mechanism of such equipment. Such engines, which were previously installed on various equipment, are likely to be found in the garage or workshop of any home craftsman.

Asynchronous motors, which are equipped with washing machines. If you have such a motor, you can confidently use it to make home drilling equipment. Making drilling equipment with such an engine at home is somewhat more difficult than using a drill, but the power of such a machine will be much higher.

Given the fact that an induction motor weighs more than a conventional drill, you will need a stronger base and stand to accommodate the feed mechanism.

In order for such a mini drilling and attachment machine to vibrate less during operation, it is necessary to install the motor on a powerful base and place it as close to the stand as possible. But here it is important to maintain the correct distance, since the convenience of installing the belt drive depends on it, due to which the rotation from the motor will be transmitted to the drilling head.

In order for you to make such a machine at home, you will need the following structural elements:

- gear;

- a hexagon on which the pulley will be placed;

- two bearings;

- two tubes, one of which must have an internal thread;

- clamping ring, which must be made of durable steel.

The hexagon also connects to a metal tube, bearing and clamping ring. Such a connection must be very reliable so that the resulting assembly does not collapse during operation.

Drilling machine with asynchronous motor

The mechanism necessary to ensure the feed of the tool in such a mini machine must consist of a tube on which cuts are first made, and a gear. The tube will move due to the connection of its teeth with these cuts. An axle with a hexagon is then pressed into this tube, the height of which must correspond to the amount of the required tool feed.

Example of a drilling machine with an asynchronous motor

Let's consider one of the very serious options for a homemade drilling machine with an asynchronous motor, which was clearly not made by a beginner. Few home craftsmen would dare to take on such a project, but if, as they say, the urge comes, then nothing is impossible.

Difficult to manufacture homemade machine with an asynchronous motor

It is quite obvious that it is quite difficult to manufacture such a machine, and then it is even more difficult to ensure the accuracy of its operation. That's why the best option is to use an electric drill to make a home drilling machine.

Finally, we suggest watching a couple more videos in which craftsmen demonstrate their homemade drilling machines. These videos are in Once again prove what to collect with my own hands the necessary equipment is always possible, although sometimes not easy.

Homemade drilling machine from a drill

It does not always make sense or expediency to buy a factory-made drilling machine. You can make a vertical drilling machine from a drill with your own hands. To do this you will need a drill and materials to make a stand. Such equipment is recommended for use in home workshops or garages, when drilling is not the main operation or is performed quite rarely and the accuracy of the hole can be neglected.

To speed up the process, just buy a specialized stand for a drill at a tool store. The result is something like a household level vertical drilling machine, which is not inferior in drilling accuracy to machines for home workshops.

The photo shows factory-made drill stands. They can be purchased at any online tool store at prices starting from $200.

The article is intended to give you ideas on how to make a drilling machine yourself from a drill, so we do not give a clear algorithm for its manufacture, because it is made from scrap materials: some craftsmen will have it, others will not. Therefore, we give basic ideas, and everyone will apply their own design solutions and make their own vertical homemade drilling machine.

If you are not looking for easy ways, then we will make a homemade stand. The stand can be made of wood or metal. Wood will be cheaper and easier to manufacture, but durability will suffer.

Metal ones are more complex, but have an incomparably longer service life and strength characteristics. The choice of stand material also depends on the workpieces being processed: when constantly drilling metal, it is better to make a metal one.

Machine assembly

The metal stands are assembled from angles for the carriage, 50x50 square pipe for the stand and 10x10 for the drill bracket, strip for the base and eyes. The base and bracket are welded, after which all elements are assembled and bolted together. It is recommended to make several brackets with different adapters (clamping rings) for different types drills. The carriage moves along the rod using a steel cable wound around the handle drum. So that the carriage does not have play and does not fall under own weight down, drill it, cut a thread and tighten a bolt (or several bolts). This selects the backlash between the carriage and the stand of the future drilling machine. The handle for moving the carriage is made from rolled products with a diameter of 6 – 8 mm.

Having several brackets with different clamping rings allows you to flexibly select drills and process almost any material.

In the future, home-made equipment can be upgraded and modified, for example, by marking or installing a scale that will indicate the length of movement of the carriage. This helps when drilling blind holes.

There are several mounting methods:

- several clamps;

- on a metal bracket in the hole under the neck of the drill.

Video of a design version of a drill on a wooden stand.

The easiest way to make a homemade drilling structure at home

A homemade drilling machine made from a drill will never replace a factory one and will always be inferior in build quality and drilling accuracy. The main advantage of homemade is low price, the ability to drill holes when the factory machine is not available for one reason or another.

You may also be interested in the following articles:

Homemade drilling machine from a steering rack

Homemade drilling machine from a steering rack  Choosing a drilling machine

Choosing a drilling machine  Lathes from a drill How to make a homemade four-sided lathe

Lathes from a drill How to make a homemade four-sided lathe

Do-it-yourself drilling machine from a drill

Dear visitors to the site “Visiting Samodelkin,” from the material presented by the author, you will learn how you can independently make a budget drilling machine from an ordinary electric drill.

Every craftsman would like to have such a machine in his household, because in comparison with factory analogues it will cost tens of times less, and if all the spare parts and components are available, then it will be completely free.

The author of this machine is Igor Stasyuk, for which I thank him very much, he shared step-by-step photographs of the assembly of the machine with the people. The design is quite interesting and at the same time simple. Corners and 4 legs are welded onto a base made of a 3 mm sheet of metal, a 500 mm rod from a professional square pipe is welded onto this plate, the slider is made of 2 corners welded into a pipe and placed on the lifting column with a gap so that the slider can move upward along the column and down. Lifting mechanism it is activated by a cable stretched from the top point to the bottom, and on the slider the cable makes several turns.

So, let's take a closer look at what exactly the author needed to assemble the machine? As well as the whole step-by-step process.

Materials

1. sheet metal 3 mm

2. fittings

3. corner

4. cable

5. drill

6. vice for workpieces

7. bolts, nuts, washers, engravers

8. drill clamp

9. paint

10. professional square pipe

11. drill

Tools

1. welding machine

2. grinder (angle grinder)

3. drill

4. file

5. vise

6. clamp

7. caliper

8. ruler

9. corner

10. level

11. sandpaper

12. brush

13. hacksaw for metal

14. emery

The process of creating a drilling machine from a drill.

And so, first of all, the author makes the base of the machine from sheet metal 3 mm, cuts out the workpiece using a grinder (angle grinder) and welds 2 corners and 4 legs from a steel rod or fittings into the lower part. The length of the legs should be the same so that there is no distortion of the frame.

The corners and legs are welded on.

Making a slider! Take 2 corners and apply them to a professional square-section pipe that will serve as a lifting column and tighten them with a clamp.

It is tacked along the edges by welding in order to simply attach it for now, and only then specifically weld the normal seam.

This is actually how the preparation turned out.

The lifting column is made from professional square-section pipe 500 mm long.

A bracket with a movable shaft is welded onto the slider body, onto which the cable turns will be made.

IN drilled hole thread is cut.

The handles of the lifting mechanism are made of reinforcement.

There is a head on the shaft that will serve as the base for the handles.

And so, 3 handles are welded on for the convenience of raising and lowering the drill through the mechanism.

Installed on a lifting column.

A loop like this is made at the end of the cable.

Attention! The cable is attached at the bottom using a loop, then several turns are made on the shaft and tension is applied in the upper part of the lifting column.

I hope the lifting principle is clear and without explanation)

A square pipe is welded onto the corner.

This is actually the mount for the electric drill.

Then the drill is installed and secured with a clamp of bolts and nuts.

Now let's go back to the lifting mechanism again.

At the top of the lifting column, a nut is welded and a bolt is screwed into it, a cable is attached to the bolt itself, and when the bolt is tightened and unscrewed, the cable is tensioned to the optimal level.

It is advisable to pre-lubricate the moving components with grease or lithol.

These small vices can be purchased at a hardware store in the tools section.

All parts were polished by the master using sandpaper and then painted.

And now the vice is screwed into its rightful place. And now the Author is already drilling holes in wooden handles for the machine.

Installation of wooden heads on handles.

In fact, our master turned out to be such a wonderful machine.

Do more creativity, improve yourself, create and success will definitely come to you.

This concludes the article. Thank you very much for your attention!

Come visit more often, don't miss out on new items in the world of homemade products!

The article is presented for informational purposes only!

Good afternoon everyone! In this review I will show how I managed to make a small simple drilling machine from a purchased drill stand and an existing but rarely used one. hand electric drill. I tried to make it complete and convenient device for amateur and household needs, without claims for professional use. As always, the review contains a description of the process, drawings, and the result obtained.

All previous years, for drilling holes, I got by with a screwdriver, and very rarely with a hand drill. This was quite enough; there were no problems on parts with a small thickness. Another issue is drilling clearly vertical holes in thick material; sometimes you can control the verticality of the drill, sometimes not so much.

Drilling a smaller hole with a larger diameter drill: often, when drilling, the original center of the hole could shift, depending on how the drill finds itself there.

To avoid all these problems, critical parts and workpieces must be drilled on a drilling machine, which naturally does not exist.

I have already reached the point where I need a drilling machine, but I don’t know exactly what I want from it, what parameters are important to me, and which one I should choose. Therefore, in order to gain experience and shape my future needs, for a better and more effective investment in a drilling machine in the future, I decided to practice on a homemade machine from a stand for a hand drill.

I could just buy a stand, place the drill in it and use it, but I needed to make it easy to turn the drill on and off, as well as conveniently adjust the rotation speed. Therefore, I decided to make a small pedestal for the stand, with controls placed in it, as well as a box for drills and other accessories.

And at the very base of the rack I decided to make a wider table for placing and fixing workpieces for drilling. During the design process, we came up with this design (the stand and drill in the model are different, taken from 3D Warehouse):

The design of the box is as follows, with an organizer installed in it for frequently used drills:

Drawings with dimensions:

After studying the Internet and reviews, we chose a well-known drill stand with an all-metal column and a cast iron base and carriage. ()

A few unboxing and assembly photos:

People in reviews write about play in the plastic guide of the carriage, and a small play at the column-carriage point, but not for everyone. I got a play in the plastic guide, which was cured simply by placing a piece of plastic from a paper folder. The play disappeared completely, the carriage began to move up and down with difficulty, but thick silicone grease eliminated this problem. The stand is excellent, heavy, monumental!

The working part of our machine was an old but vigorous drill Interskol DU13/780ER:

The drill fits tightly into the receiving socket on the stand, there is no play, the fixation is excellent:

We begin to assemble our pedestal with a box. We file the details of the pedestal. In the project, I laid plywood with a thickness of 10 mm, but it so happened that I had an already started sheet of 12 mm, which for some reason I mistook for 10 mm, because of this my dimensions were floating and for a long time I could not understand why):

We assemble using self-tapping screws and PVA:

We file the details of the internal drawer, the bottom of the box is made of 6mm plywood:

Assembling the box:

Prepare and glue the back and front plugs of the pedestal:

For the drawer we use furniture ball guides:

To attach the box to the hinges, I placed a sheet of plywood next to it and placed four 10-ruble coins to create an even gap between the box and the base of the pedestal:

We cut out and glue the front panel of the drawer onto PVA; we also adjust the gaps with coins:

Don't forget to make a handle to open the drawer:

As a filling for controlling on/off and adjusting the speed, I picked up this kit from the bins: a relay with a 230V coil, two buttons, with NO and NC contacts, and a triac speed controller (2000W) from Aliexpress:

On the front panel we mark the holes for the buttons and the regulator potentiometer:

We drill holes. I had to make a small recess under the potentiometer handle with a Dremel and a cutter, since the thickness of the front panel is 6 mm, and the handle did not fit properly onto the potentiometer shaft:

Let's try the buttons:

On the back plug of the button block I decided to install a socket for the drill plug, as well as a gland entry for the mains power cable:

We take the top cover of the pedestal, mark and drill holes for attaching the base of the stand (I did not glue the top cover of the pedestal, attached it only with self-tapping screws):

Let's move on to making the drilling table. We will make it from two sheets of plywood:

We connect two sheets with four self-tapping screws, mark and cut out a groove under the column of our rack with a jigsaw, and finish it with a Dremel:

Mark the rounding of the corners:

We mark, take a router and use a 10mm groove cutter along the plywood stop to make grooves for moving table clamps, as well as table roundings:

We disassemble our part, take the bottom sheet, mark and drill holes in it for attaching the table to the base of the stand:

On the reverse side, for fastening I used the following fasteners with an M8 thread to recess the caps and made indentations with a Dremel:

Let's take it top sheet table, mark and cut out square hole 70x70 mm for a replaceable liner. We place the insert offset relative to the center so that it can be turned over and all sides of the square of the insert can be used:

We glue both sheets of our table using PVA:

We are preparing clamps for the table. I made them from scraps of plywood, beveled the resulting heel a little to get a good clamp. fine details. The 8mm hole for the clamping bolt was slightly worked out in the longitudinal direction so that the bolt in the part could deviate relative to the vertical axis.

Let's try our clamp in action, using a long M8 furniture bolt, washers and a wing nut:

We take all the received machine parts, grind them and coat them with oil:

We install all the components of the power and control system, buttons and relays are connected according to a self-retaining circuit:

We check the inclusion, install everything and fix the wires:

We place rubberized legs at the bottom of the pedestal:

We fasten the drill table to the base of the stand with M8 nuts:

We insert the box and see what has happened so far:

Let's move on to making an organizer for drills. All parts of the horizontal compartment of the organizer are made of 6mm plywood. We cut out the base according to the drawing, cut thin strips of plywood, and assemble the sides using PVA:

We saw 6mm wide dividers on the table (for such operations I had to make a zero-gap liner from aluminum on the sawing table, since the original surface of the table had already worn out and the plywood had become severely chipped):

We glue the separators using a 14 mm template using PVA. I took the depth and width (6x14 mm) of the compartment based on my fingers, so that I could easily take a small drill from the bottom of the compartment:

I decided to make a vertical organizer for the most common drills (two compartments for drills for metal and wood) from 12 mm plywood, but glue a strip of 6 mm plywood on top, since drilling into the end of the plywood is very difficult:

Let's try our vertical organizer against a horizontal one:

We mark and drill holes in the organizer on our table using all available drills, from 8mm to 1mm with a diameter increment of 1 mm:

Let's try both organizers in a drawer:

We coat the new parts with oil and put them in a box. We place the vertical organizer on small hinges so that it can be folded into a completely vertical position and have access to the drills in the lower compartment.

In front of the horizontal organizer, I glued a stop made of a piece of 6mm plywood in the box; after it, in the box a little later there will be an organizer for cutters, countersinks and other large drills. I also prepared several square replacement inserts:

We assemble all the parts of the machine, roll up and fasten the drill cable so that it does not interfere:

We work:

The drilling machine turned out to be suitable. Drilling this way is much more convenient, and most importantly, more accurate and accurate. Of course, there is no speed control, it would be even more comfortable with it, but I’m already starting to get used to what speed should be set on the drill and the immersion force for the material, so as not to sag the drill, but also not to spoil the workpiece or part with high speeds. This is all worked out through experience. I’ll work on it, understand what I need and what’s important from the machine, what parameters will be critical for me, so that I can possibly consider an “adult” machine in the future.

My immediate plans are to make a small vice for vertical fastening of workpieces and a grinding drum for the machine; I need them for upcoming projects.

Sometimes there is a need to cut a fairly hard board into several planks. It’s impossible to do this kind of work manually, and it’s unprofitable to buy a factory-made circular saw just for a single case. The solution is very simple - make a small circular saw from a regular drill.

It is better to make the machine small in size so that it can be put on a shelf when its presence is no longer needed. Its design is extremely simple:

- base made of a thick board or piece of chipboard;

- working surface;

- racks;

- shaft with circular saw;

- electric drive in the form of a drill.

We make the base from a sheet of chipboard 30 mm thick; it is enough to cut out a piece measuring 300x250 mm. For desktop We choose a sheet of duralumin 4 mm thick - it is quite rigid and light, so as not to weigh down the entire structure. In the right place we make a hole for the circular saw measuring approximately 160x10 mm.

The holder for the drill itself can be made independently - all the necessary dimensions and drawings are available on the Internet, but a similar design for the shaft with a saw can be purchased in a store or at a clothing market. The bearing for the shaft must be selected dustproof- when the homemade machine is working, there will be a lot of small waste in the form of wood dust.

A circular saw from a drill is assembled according to the standard scheme: first, all parts are fixed to the base, then the work table is mounted and the drill is connected.

Security measures

When working on any machine, you must strictly follow the following rules:

- the place of upcoming work must be cleared of unnecessary materials and tools;

- workpieces are fed smoothly without jerking or distortion, so that the cutting tool does not jam;

- the plane of rotation of the circular saw must be limited from above by a special protective casing;

- the machine must be kept clean and put away after each use;

- If the mini sawmill is not used for a long time, then lubricate all metal parts with machine oil.

This small machine can cut more than just wooden boards. If you install special cutters on it, you can process parts made of brass and other non-ferrous metals, plastic or propylene.

Other homemade machines

Many users are interested in what else can be done using improvised tools from a drill with their own hands? There are many answers - home craftsmen are already making various homemade products from drills in garage workshops. A drill is a universal tool, so with a certain skill and imagination you can make whatever your heart desires.

- Sharpener, you just need to buy emery in the form of a circle and make a special holder in which the drill is attached.

- Drillingmachine- there are special holders for vertical drilling or stands.

- Turningmachine small size for wood processing.

- Mini drill for various needs of the home handyman.

- To mow the grass around your garden without any problems, you can do it yourself drill trimmer.

- Grinder from a drill It’s done quickly, just buy specific attachments.

- Garage car repair technicians install original winches to replace engines based on old, very powerful tools.

- Gardeners make holes for planting young trees using homemade drill bit.

- When pouring the foundation for a utility room in the private sector, some users use homemade vibrator, made from a drill to quickly compact a concrete structure.

Original devices

The list of homemade products can be continued endlessly, but we’d rather talk in more detail about some homemade machines that can be made from any model of drill.

A drill made from a drill is not a fantasy, but a real and fairly universal machine, assembled independently. The main thing is that you need to order from Chinese engineers (if you couldn’t find it in your city) flexible shaft from a standard medical unit. As a result, a drill appears in your arsenal, which can be used for engraving work or drill holes using special burs in small parts or structures that cannot be reached with a standard drill.

A woodworking or lathe for home can easily be made using a drill. The tool must be secured with special clamps quite rigidly and inserted into a chuck of a special design holder with several sharp pins that keep the workpiece from turning. The center of the rear holder (headstock) and the clamp at the front of a homemade lathe should be located on the same axis. Precision is necessary to prevent runout as the workpiece rotates. After installing the part, tailstock It is firmly fixed with a special clamp.

The third element of the machine is handyman in the form of a wooden block on which a chisel or other tool for processing the workpiece will rest.

Important! When working on a lathe, do not forget about safety, be sure to wear safety glasses, and the sleeves of clothing should fit tightly around your forearms.

Turning a machine for processing wooden workpieces will work properly if the drill has a built-in electronic speed controller. Using the trial method, you establish the optimal rotation mode for effective wood processing. Using such a woodworking device, you can make unique products for household needs: for example, a rolling pin or pestle with a mortar, a candlestick or a prefabricated candelabra.

Winch

An original winch based on an old but powerful drill will become an indispensable assistant in the household, especially for those users who live in their own home and have a personal plot. A simple situation: you decided to install a larger container in your summer shower, but raising it to such a height alone is problematic. Using a winch, this can be done in a few minutes. You just need to first calculate the weight of the container and the spindle speed.

According to garage craftsmen, a homemade winch can easily lift the engine from a passenger car. Watch the video if you don't take my word for it:

Experts advise using a homemade device, installing the drill at the most minimum speed. This design can move objects with different masses, because craftsmen even make winches based on an ordinary car starter.