Dear Clients. We have stopped accepting orders for now, but hope to resume them in the future. We are not working now.

How to use online furniture designers

You buy inexpensive furniture without sacrificing quality because:

Save on paying for expensive designer and surveyor services.

You get the opportunity to furnish your home in stages.

You independently select the parameters of your furniture.

You design furniture according to your taste.

You have access to all the accessories that are on the market.

You can see online how the price is formed.

You buy inexpensive and high-quality furniture.

TOP 4 advantages of cooperation with the Furniture Details company

You pay a fair, not overpriced, price for furniture.

You watch how the price of the product changes online. It's easy for you to fit into your budget.

You do not pay for the services of operators and managers and save money.

You use the “Constructor”, where you create a drawing and receive a furniture assembly diagram.

Why are Furniture Details products more profitable than ready-made furniture?

- You choose the sizes yourself.

- You don't depend on the designer.

- You get the opportunity to choose the material or accessories at your discretion.

- You save on your purchase.

Why are Furniture Details products more profitable than custom-ordering furniture?

- You save on the services of a measurer, designer and assembler.

- You immediately know how much you have to pay.

- You will not face any unpleasant surprise in the form of a “price verdict”.

Feedback from our clients:

- Ordered a large quantity bedside tables for a child care facility. The budget was limited. “Store prices” simply weren’t worth it. The designer literally saved the situation. Developed

simple model - We've been dreaming about a large corner wardrobe for several years now. But financial possibilities left much to be desired.

- You can’t find suitable models in stores, and they didn’t dare order a custom-made corner structure. The prices there are so high that it’s easier to buy a plane. We tried “Constructor” just out of interest. The cost was a pleasant surprise. They took a risk. Ordered. We've been using it for six months now - everything is perfect.

- Anton, Moscow Even in this company sliding doors

really cheaper than in the store.

We couldn’t even imagine that we could independently influence the price of some doors.

We are used to the fact that in markets we have to pay for what we have. We saved money, bought a wardrobe right away, and also had enough for a bedside table. Ksenia, Moscow

Today, almost no one offers the service of manufacturing furniture according to drawings. But our company has a lot of comments about store models, and even catalogs with a “wide range” do not correct the situation. We are already sending the third drawing to “Furniture Detail”, they all make it to size, even sometimes

- good advice give. As a result, our office probably has the best furniture in Moscow. And inexpensive!

- Dmitry Valentinovich, Moscow The built-in designer of the wardrobe and its doors is do-it-yourself furniture and designed for an individual place 3D designer of a sliding wardrobe 3D designer of a door for a sliding wardrobe online 3D constructor

- corner cabinet online

Many homes have handmade furniture. Instead of buying

ready-made sets

Making things with your own hands is a unique opportunity that has begun to be valued in society on a wider scale than before. This is what such work under the motto “Do it yourself” means:

- Not much limited creative possibilities. Most often, the master himself comes up with wardrobes that he will make while doing the designer’s work. You can ask for design help from professionals or implement a professional design development yourself

- Exceptional pleasure from high-quality manual work

- The opportunity to save money on paying for custom-made furniture, “outsourced”.

The increase in the number of people who want to make furniture themselves is also explained by the availability of any tool, including the one so necessary for the home craftsman - a powerful and accurate portable power tool.

Making furniture yourself is a multi-step process. Before making furniture, you need to come up with it, solving many problems - from the interior of the room to the features of assembly on site. Making furniture can also be different - leisurely, slow work the old fashioned way, hand tools or fast, intense work using numerous power tools and modern fasteners. And always – accurate and difficult calculations.

Much depends on the time that you can devote to making furniture yourself. Some home craftsmen would love to build a lot themselves, but they do not have the opportunity to devote sufficient time to this most interesting activity.

Good opportunities for creating furniture quickly and efficiently appeared with the development of composite materials - almost all cabinet furniture is made from these hard and durable boards with completely finished decorative front surfaces today.

Modern capabilities make it possible to reduce all work on creating furniture from composite materials to on-site assembly - there is automatic systems design, including design, providing detail and making the work much easier. Furniture blanks can be ordered based on the results of development on such a designer.

In addition to the final goal - creating furniture - the designer also provides an intermediate result - fairly detailed drawings that can repeatedly help the home craftsman in many matters.

Everything made of wood with your own hands

Previously, all furniture was made of wood. IN modern world for arrangement household In the manufacture of furniture, other materials are also used - metal, glass, plastics, and most often - advanced composite materials. These materials are fibreboards and particle boards different types(chipboard, MDF) allow the production of most types of furniture products.

Here are the advantages of using composite materials:

- Very high level and quality appearance– these are absolutely smooth slabs with a durable finish in a huge range of patterns, colors and even textures

- High technology for working with such materials - instrumental cutting, drilling and milling operations are performed almost instantly, even using hand-held power tools

- Simplicity of not only manufacturing, but also design - you can do and invent without having to develop and manufacture individual parts.

One of the main advantages composite material is that furniture made from it continues to be considered and perceived as wooden! This feeling is stronger the closer the pattern of the finished surface of such a material is to the appearance of real wood.

But sheet materials with a pattern different from wood are no worse! They open up many decorative and design perspectives. Today, the use of such materials is wider than the use of boards with wood grain. Composite boards with such a free pattern or surface color have many advantages:

- Various and unlimited colors and patterns, textures and designs

- Wide possibilities not only for integration into the interior, but also for creating and shaping the interior around such material. Such an active role is usually played by bright, explicit colors - white, blue, red, yellow.

- Board materials can be made completely unique by painting them yourself or using appliqué or any other method. The main thing is that such individual finishing is carried out after cutting the sheets into blanks.

- The form in which such materials are produced - mainly slabs - makes it easy for an independent craftsman to work with them. Understanding the peculiarities of the junction of flat elements - shields, plates, the master can come up with and assemble forms of any complexity. Despite the planar nature of composite materials, they can be assembled into faceted shapes that resemble curved ones.

Effectively complete work on furniture self-made possible with the help of detail. Accessories, constipations, decorative overlays and other furniture details give the completed work its final look.

You can independently make any type of furniture with clear design and technological limitations. The most common furniture is cabinets. This is absolutely necessary furniture in any home, for the manufacture of which composite sheet materials are ideally suited.

Home craftsman equipment and tools for making furniture

Every home has a hammer and a screwdriver. The home craftsman who loves tools has a little more. Depending on the profile and personal preferences of the craftsman, his toolkit is formed - with carpentry or with a metalwork “accent”, with equipment for welding, soldering, working with electronics and electrical systems.

To work with furniture, you also need an appropriate tool park. Particular attention must be paid to measuring and marking tools, which are also represented by the most different devices and devices:

- In addition to the natural need for roulettes different lengths, you need different rulers, preferably metal ones - you can cut them with a knife and make markings metal tool. It is important to have metal squares, at least to determine right angle. The larger the square, the more accurately it will work. A protractor will also come in handy to help you find any angle.

- For accurate measurements, it is important to have a caliper, and for particularly demanding craftsmen, even a micrometer. Many people use various mandrels and templates designed to work with standard parts - holes, sockets and grooves, for example, for inserting furniture hinges

- A thicknesser is very useful - a simple device for marking parallel lines

- You need a tool for spatial measurements and markings - bubble and water levels, a plumb line. Modern technology has produced many laser devices - rangefinders, levels, etc. This tool is also necessary for working with built-in cabinets and other large forms.

A simple set of tools is needed in any home. The craftsman should have not just one hammer, but several of different weights, a set of screwdrivers, possibly with interchangeable heads. Such a set should be complemented by a set of keys, which also have different types of heads. Here are the other tools you need:

- Various types of hacksaws for wood and metal

- Planer and knives

- Hatchet and chisels

- Files and sandpaper.

It’s good if the master has the need and opportunity to have a power tool. At a minimum, you can have a screwdriver - it can be used like a drill. A jigsaw, a real drill, and a sharpener wouldn't hurt. It’s very good if you have a hammer drill, grinding machines, cutting equipment – “grinder” and small circular saw.

The owner of such a set can perform almost any operation that may be needed during the manufacture and installation of furniture. Of course, there should be room for tools in the designed cabinets.

How to work competently with your own hands

Making furniture yourself is a common creative and design process. It consists in the implementation of an invented idea. Here are the main stages of developing such an idea and manufacturing the planned furniture:

Sketch development. The idea of independently developed furniture must necessarily be individual in nature. Otherwise, it is difficult to explain why it was necessary to do this - after all, modern furniture production can fulfill any order for products in a single copy.

Comprehensive check and consideration of the sketch. For example, you need to make sure that all the required accessories are on sale. It is very important to study how furniture of this chosen type is made, how the structural units and parts are arranged.

By thinking and analyzing the sketch, you can achieve competent and effective solution, trusting his final drawing.

The capabilities of modern online designers allow those who wish to combine a sketch and a project into one operation. The designer does his work automatically and the home master will receive all the drawings at once.

The designer provides not only drawings, but also the production of blanks with the required accuracy - the master only needs to make the most interesting job– assembly and final finishing.

The home craftsman has a huge advantage - he is on site and can comprehensively think through the design. Those who are not sure of the correctness of decisions can use a method that is not always available to professional furniture manufacturers and assemblers - modeling in kind.

One of the techniques for such modeling is to depict the dimensions and parts of future furniture directly on the walls and floor of the room. This way you can make sure that the size of the furniture and its structure correspond to the idea and do not detract from the room.

The second technique is even more obvious. It consists of making life-size mock-ups of future furniture using cardboard, scraps of plywood, paper and any available materials. You can even outline the contours of such furniture using stretched cords.

When all doubts have been dispelled and the decision has been made, you can order the blanks. When working with composite materials, one of the important tasks is accurate cutting of slabs into blanks, with an acceptable error of less than a millimeter. Even with good hand power tools Such work is difficult to perform efficiently, and this operation is very important for ensuring quality. Even some professional furniture manufacturing companies outsource cutting. The fact is that high-quality cutting is done on a special stand, a cutting machine. This is a complex complex, the installation of which requires a specially designated area and equipped dust removal. The cost of such a cutting complex is quite high and it is good where it will be fully loaded.

For a home craftsman, this technological idea is also very effective. A few days after finishing work on the drawings and sending the application, you can receive all the details delivered to your home.

The home handyman enjoys the important advantage of choosing fittings. For many types of furniture, the importance of fittings is decisive - from appearance to design.

Types of DIY furniture

A DIY furniture designer can do a lot. The most common type of furniture, the development and production of which does not require special equipment and conditions - this is cabinet furniture, that is, one whose design provides for the presence of a body. These are various cabinets, drawers, shelves, desks, dressers and much more.

Sliding wardrobes have become widespread recently. This is an ingenious design that allows you to use niches and recesses in the walls to build cabinets. If there are no such niches, then a cabinet of this type is simply attached to the wall, sometimes adjacent to the corner. There are also corner solutions for such cabinets.

The efficiency of this type of cabinet furniture is much higher than that of a conventional cabinet. This is explained by the fact that the wardrobe can completely occupy the space intended for it, without gaps or gaps, and its internal organization completely focused on the needs of the owners.

The equipment of the sliding wardrobe is the same as for conventional wardrobes:

- Hangers and rods for hanging clothes on hangers, including lowering rods – pantographs

- Shelves, including special ones for shoes

- Pull-out elements - drawers and baskets

- Fittings and accessories - hooks, pull-out rods, mirrors, etc.

Wardrobe technology allows you to develop and build a wide variety of furniture compositions - wardrobes, kitchen sets, book, household, universal storage containers. It is also possible to make unique designs, cabinets - partitions between rooms with access from both sides. Quite unusual solutions can be implemented - including furniture with inclined walls and much more.

The table shows some examples of furniture that a home craftsman can make using an online designer:

| № | Type of furniture | Characteristics and Features |

| 1 | Writing and dining tables | Desk tables turn out well, but dining tables most often require a supporting structure made of wood or metal - the strength of small-sized joints is limited |

| 2 | Armchairs | It is not difficult to make chairs of massive stationary structures - it is easier to ensure strength for them |

| 3 | Chairs and stools | It is possible to manufacture only some models of chairs and stools from MDF or chipboard - due to the high requirements for the strength of joints in knots |

| 4 | Shelves, shelves, home and office sets | It is possible to manufacture in any configuration, in closed (with doors) and open versions, in all the wealth of choice exterior finishing by color and pattern |

| 5 | Beds | It is possible to make beds provided that reliable support is provided for the mattress or the spring frame underneath it - slabs made of composite material do not bend well. |

doors and cabinet design – 3D image

For the home craftsman and the professional, working with an online designer is crucial. In addition to ensuring competent design and elaboration of workpieces, there is an ongoing opportunity to evaluate the appearance and structure. This is possible thanks to the three-dimensional design tools. The model built on it can be rotated and evaluated from all sides.

Both for the amateur craftsman and for experienced designer this opportunity is very important - in addition to assessing appearance, you can once again check the decisions made and implemented. Even such a simplified three-dimensional model, which is built by an online designer, can be agreed upon with other people - it provides complete clarity of the designed object and accurately reflects the dimensions to scale.

The 3D mechanics of our design software make it much easier to work with parts, for example - when designing workpieces, it is much easier to identify those edges that require finishing.

In general, it is the three-dimensional nature of online designers that will make it possible to produce the most complex and detail-rich designs - the design machine does not fail on its own.

Free furniture design programs

Our online designers are simplified as much as possible so that they can be used by a master whose experience in computer design is minimal. For this purpose, the designer is made up of several modules that work as independent programs. Here are the programs that work today:

- Corner cupboard

- Sliding door

- Detail

These design tools are compatible, the results of one can be used in the work of the other. Another important benefit of simplified 3D modeling and detailing is cost savings. Not only do you not need to pay a measurer or designer, but also the parts are paid only according to their parameters, and not according to the cost of every centimeter of seams and trims after its manufacture.

The cost is constantly indicated on the screen and instantly reacts to any changes. The user can fully and timely adjust the volume and design of the cabinet, guided by cost indicators.

The main advantages of our designers are the general cabinet design program

One of the most important advantages of our designers is the ability for craftsmen to work with them without training. Those who take advantage of this benefit will be able to receive the following significant assistance in their work:

- Making your own furniture is a significant cost saving option. This idea of savings is perfectly matched by computer-aided design technology - its operation does not require a staff of employees, an office or warehouses, which means that the final cost will be even less

- Possibility of constant cost control – parts and the entire object

- Completely free choice of fittings

- Opportunity step-by-step production details and step-by-step implementation. Professionals try not to provide such services.

- Obtaining clear drawings, detailing and assembly.

The benefits of working with a designer are felt by the home craftsman from the very first minute of work - these programs are understandable and the designer can design any object in different configurations, making the most of the opportunities to correlate the results of such design with nature. Even experts admit that the simplicity and associated speed of the program make it necessary - this is an excellent opportunity to quickly control cost during design. Professional design programs do not work so quickly and with sufficient completeness of data, and architects and designers are happy to use our simple programs to solve the most complex professional problems.

For amateurs and even professionals, the ability to step-by-step work on the project. A master, if he is not sure of the correctness of his decisions, can construct his furniture in parts, spending, for example, several hours in the evening over several days. Defects and subsequent alterations do not delay anyone except the master himself - an online electronic designer can serve many visitors at the same time.

Phased implementation is important for those who are not confident in their decisions and are afraid of making a fatal mistake.

Experts understand the huge time savings that come from clicking the “Add to Cart” button. In one motion, an order for the production of those blanks that have just been developed and tested is actually completely placed. Organized delivery of cut blanks to your home or site perfectly complements the possibilities of designing cabinets and other furniture elements.

The designer makes it possible to design furniture complexes without restrictions in the degree of detail. Even when working on very large complexes, the detailing principle adopted in the designer for an object of any size applies. At any scale, you can compose, detail, evaluate three-dimensional schematic models, think about edges, color and texture. The saved data can be used more than once.

This possibility may arise, for example, if the furnishing of premises with furniture is done in stages.

Using an online designer and ordering furniture blanks calculated with its help has another advantage. The fact is that the accuracy and precision of the workpieces is so high, and the designer allows you to think through the design so deeply that assembly does not require even a small part of the tools listed here. This is another advantage of this modern instrument design.

In reality, to assemble furniture and attach it to the walls, you need a very simple set of tools:

- Hammer

- Screwdrivers

- Possibly a key with interchangeable heads.

Having prepared this tool and well-designed fasteners in the form of dowels and screws, you can completely assemble a built-in wardrobe of any complexity.

Transformation of the wardrobe and its doors

If the need for a wardrobe has disappeared or the requirements for its configuration have changed over time, it is not difficult to remodel it. It is best to anticipate this possibility in advance when working with an online constructor. The most important thing that can be useful for transformation is the distance between the vertical internal walls - the racks. This distance should be calculated for the installation of ready-made pull-out baskets and drawers. Then, even if such sections are made for clothing, over time they can be converted for other household needs by installing shelves and pull-out containers in them.

The shelves can be swapped by pre-ordering holes in the vertical inner walls of the cabinet for fastening the shelves. In the same way, you can provide for the movement of rods and clothes hangers. All these ideas can be perfectly implemented with the help of an online designer. The result of a thoughtful transformation of the built-in wardrobe should be a second set of drawings, developed with the same overall dimensions as the first, main version.

Instructions for designing a cabinet online using a furniture designer

A free 3D furniture designer will allow you to independently calculate and model a cabinet that suits your interior. This best option, If you want to unusual solution, but there is no opportunity to resort to the services of a professional designer. The online furniture designer allows you to design your own unique cabinet and place an order for its production. In addition, the site also features

That is why furniture design software is an excellent solution for choosing the ideal solutions for your own “nest”. Today there are quite a lot of utilities that, without the help of specialists in the field of furniture design, allow you to create the required models.

Program interface for creating drawings and furniture projects

The most important thing is to choose among the many proposals the program that will be most understandable and will correspond to the user’s wishes.

Previously, in order to come up with this or that model of furniture for the home, you had to have many skills:

- Be able to draw drawings on a sheet of paper.

- Be fluent in geometry.

- Understand the scale and parameters of furniture items.

- Take measurements manually using a tape measure.

- Use your imagination to imagine which color schemes are the most attractive.

Modern times dictate new rules. Now making a furniture project is quite simple:

- Measure the height, length and width of the walls, enter this data into the program. Utilities will do the rest, calculating the size and quantity necessary materials in order to collect created projects.

Kitchen design in the House 3D program

- After this, you can place the necessary pieces of furniture in the space, viewing them from the desired angle. This will help you visualize ideas, bringing you one step closer to realizing transformation.

In addition to the fact that furniture design software helps facilitate the process of creating a wide variety of models of interior items, including useful functions may also include:

All these factors indicate that using such programs is a pleasure. In addition, the number of software for carrying out this mission on the Internet is quite large. Everyone will be able to choose what best suits their preferences.

Who will need these programs

Furniture modeling programs can serve many purposes. Most often, such utilities are used:

In general, software for designing and modeling furniture for the home and office can be used by absolutely anyone who has access to the Internet.

What programs are there for furniture design?

Since the demand for the use of furniture design utilities is quite high, naturally there are many offers. You can pay attention to the following programs.

SketchUP

SketchUP furniture design software interface

The program is quite simple and understandable, so everyone can easily use this utility.

Advantages

- Russified menu. This is an opportunity to use the utility without knowledge of foreign languages;

- clear and easy functionality, thanks to which everyone, even an inexperienced Internet user, can use it for their home;

- a large number of ready-made tools in the utility library.

The video shows how to model furniture in SketchUp.

Flaws

- The images appear to be drawn rather than actual pieces of furniture. This fact may somewhat worsen the perception of the final picture of the finished furniture.

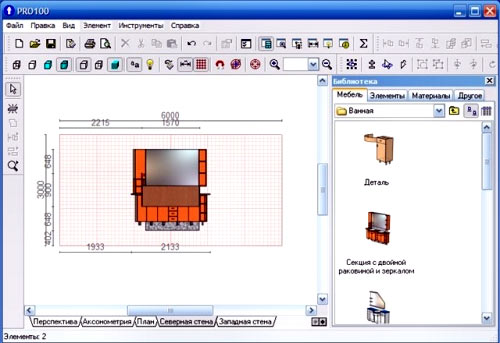

PRO100

A very popular program among users. With its help, you can see not only individual interior items, but also a complete picture of the room in which you plan to renovate.

Advantages

Flaws

- If the user wants to see calculations of the amount of materials needed to implement an idea, it is necessary to purchase a paid platform for work. Although, this can hardly be called a disadvantage, because the purchase full version opens up great opportunities.

KitchenDraw

Another program that is quite interesting in its functionality.

Advantages

Flaws

- The KitchenDraw program does not have a utility that can be downloaded to your computer and used freely. The program is paid, and payment is made not once, when purchasing the platform, but hourly. This is inconvenient, since each time you need to have money on your balance.

Each of the programs that allows you to design various items furniture has its advantages and disadvantages. Anyone who wants to use such utilities will be able to independently weigh the pros and cons of each of them.

In any case, such programs greatly facilitate the process of designing furniture and will help you independently carry out this mission.

Kitchen project created in the KitchenDraw program

Designing your own furniture for your home or apartment is very interesting. The most important thing is that a person makes the interior space of a room more harmonious and comfortable when he pours a piece of his soul into the process of thinking about the textures and type of furniture. No restrictions for modern man, all possibilities and facets are open. The most important thing is to choose a utility that will help you make the process of designing drawings for interior items as fun and easy as possible.

We previously wrote about ASSOL programs for virtual “dressing up” upholstered furniture By photo. This article will discuss special programs for automating the 3D design of upholstered furniture and technological preparation and optimization of cutting upholstery fabrics.

3D design programs are widely used in the design of cabinet furniture. However, until recently there was a certain vacuum in the field of upholstered furniture design. This is explained by the fact that the three-dimensional configuration of upholstered furniture is much more complex than cabinet furniture. And if the details of a rigid frame can be quite accurately designed in conventional 3D editors (AutoCAD, SolidWorks, etc.) - which is practiced by some designers - then the task of constructing a 3D model of a sofa can only be performed approximately and serves only for evaluation general view products.

Thus, designers and technologists of upholstered furniture are forced to work the old fashioned way, while their colleagues in cabinet furniture have long been using advanced software products in their daily work.

Demand creates supply

However, in the last six months the situation has changed dramatically. A specialized ASSOL software package for upholstered furniture has appeared. It allows you to design a 3D model based on real dimensions and then automatically obtain parts on a plane to create a set of upholstery patterns. The created patterns are assigned the necessary technological parameters to obtain layouts. Patterns of one model can be sorted by companion fabrics. In the program “Automatic layout of patterns” ASSOL, the necessary parameters of the fabric are set: width, presence and direction of pile, dimensions of the pattern, etc., sets of patterns are selected for the layout. One layout can include patterns from different models. Next, ready-made cutting cards for various widths are automatically obtained upholstery fabric with optimal fabric consumption per model. These finished cutting cards can then be printed in full size or in miniature, and also transferred to specialized cutting equipment.

Depending on the power of the computer and the configuration of the parts, the time to obtain the finished layout is 10 -40 minutes. This layout can be manually adjusted, shifted or rotated, but, as a rule, this is not required, because j. The Automatic Layout program in saving fabric is ahead of a layout specialist by an average of 1-3%. And for fabric with a pattern, where the conjugation of parts is tracked or binding to a specific point in the pattern, the machine’s winnings increase to 5-6%.

Thus, with virtually no human intervention, it is possible to obtain dense layouts of any model. The opportunities that the automatic layout of ASSOL opens up can be used not only for new models, completely designed on a computer, but also for proven “sales leaders” in the sale of models for which there are in production complete sets pattern These sets of patterns can be entered into a computer, set the necessary technological parameters and then laid out on all upholstery fabrics used in the production.

The task of entering patterns itself, if solved in the traditional way - using a scanner and digitizer, requires significant costs. Furniture patterns are quite large - scanners of this size are expensive and slow, and buying a digitizer* means shelling out $3,000 on bulky equipment that will soon become unnecessary. Back in 2000, the ASSOL Center developed an advanced technology for entering patterns into a computer using a digital camera - Photo Digitizer. Since then, not a single enterprise working for ASSOL has purchased a digitizer.

The essence of the new technology is that the patterns are placed one by one on a special marking and photographed digital camera and transferred to a computer, where the Photodigitizer program eliminates all optical and perspective distortions and automatically determines the contours of the patterns. Then all that remains is to set the technological parameters for them and transfer them to the Layouts program. In this case, the areas and perimeters of the patterns are calculated automatically.

The process of entering patterns using the Photo Digitizer is simple and straightforward. Thanks to the automatic elimination of distortions and vectorization of the contours of the patterns, they are guaranteed against human errors, which often occur with the traditional method of input from a digitizer, where the contour of the pattern is specified manually by the technologist. The costs of introducing new pattern input technology are significantly lower than the implementation of traditional input systems. By input speed new technology is also ahead of all previously adopted methods. Let’s illustrate the time required for input using the “Photo Digitizer” and the results of the pattern layout machine using a real example.

EXAMPLE

Usually, before a company purchases the ASSOL Automatic Layout, we recommend comparing the results obtained by the program with the results of the layout of this enterprise. Comparison of results is the best proof of the need to purchase the program.

The Center has accumulated data on the time it took to enter sets of patterns for different models. One of the typical examples: it was necessary to calculate layouts for different widths for a set of patterns for a model of a sofa and two armchairs.

36 different patterns were entered into the computer. Photographing the patterns took 30 minutes - a total of 25 photos were taken, long patterns were photographed in parts. By the way, you can take photographs from any angle, the main thing is that all the patterns and markings fall into the lens (Fig. 1 shows the stages of inputting a photograph: before processing, distortions are eliminated, contours are vectorized).

Another 30 minutes of computer time were spent on automatic elimination of distortions and vectorization of patterns in the Photo Digitizer program. (Figure 2 shows some photographs after eliminating optical distortions - the effect of a large format scanner with low resolution is achieved. Figure 3 shows the same patterns after vectorization.)

Another 65 minutes were needed to check the patterns, combine parts of the patterns, and assign technological parameters to the patterns for layout.

Total total time To enter a set of patterns of complex configuration - 2 hours.

Simple patterns (rectangular) should not be entered; they are quickly created in the ASSOL program. After that, in the Layout program we set the necessary fabric parameters and launched automatic layout for 4 different widths of pile fabric. It should be taken into account that long layouts were calculated (the length of the layout at all widths is more than 10 meters). After 3 hours the layouts were ready - see fig. 4.

Anyone interested in new production automation technologies

Anyone interested in new production automation technologies

We are waiting in our Center.

Automatic layout ASSOL is supplied both with CAD ASSOL and is connected to other systems used in the enterprise.

Enterprises that have a manual ASSOL layout receive a discount.

Staged payment is possible.

Nowadays, there are many programs to correctly calculate all the required furniture sizes for your home. Furniture design software is a tool not only for the professional furniture assembler and manufacturer. Any person who decides to furnish an apartment or house with their own hands can discover a lot of useful functions in this software.

There are both paid and free programs, which have a trial period of use. If you are creating a custom home furniture project, this free period should be enough for you.

The furniture manufacturing process includes several main stages.

Each stage of work has its own program. Using the appropriate software allows you to speed up the process of creating furniture, avoid the most common mistakes, use ready-made package solutions, making your own adjustments that will make your piece of furniture individual.

There are three main types of programs of this kind:

Large development companies specializing in design, engineering, cutting and manufacturing of furniture often offer packaged versions of their software products. When one shell and a single interface supports different mods and add-ons, it is convenient primarily because there is no need to once again solve the issue of compatibility and reading formats. These packaged software offerings automatically read the data without asking any questions.

All applications that are aimed at are designed in such a way that you can enter all the coordinates and dimensions of your room, as well as separately place and change each detail. In any case, you can find a program on the Internet and choose the one you like. There are also online services for these purposes.

The best furniture design programs

Astra Furniture Designer - a simple program for designing furniture

One of the most famous programs for designing furniture is. Such a program will serve you for designing cabinet furniture, as well as interior design. It uses tools that are very easy for average users to learn.

ASTRA program for furniture modeling

ASTRA program for furniture modeling By using even the simplest furniture design program, you can eliminate all sorts of mistakes in construction that are usually made when designing with pencil on paper.

Astra software product

A large company developing design and construction software offers a whole software package consisting of separate autonomous modules. Each client can choose exactly the kit that he needs. Available modules for furniture design, interior design, cutting sheet materials and free-form parts. Additionally, modules and macros for Excel are presented that allow simplifying the work of professionals - automating the process of monitoring the cutting process on professional machines. A bonus is the ability to export information in the correct format from Excel to the software interface.

Working window of the Astra Constructor program

Working window of the Astra Constructor program This program has two types - axonometry and perspective. Working space usually divided into four or two parts, so you can install a separate projection. It will allow you to rotate the entire scene, as well as view it from the angle you wish. This program is so simple that it will be very easy for you to explain to your master what exactly you want.

Program for professionals PRO 100

This application combines high professional level and ease of maintenance.

This is one of the best furniture design software as it is equipped with all sorts of additional features and is also constantly updated to follow the latest trends in the world of interior design and design. This program was developed by Polish programmers and engineers.

Advantages of the PRO100 program

Compared to more universal Arson programs, this application is characterized by greater simplicity and flexibility. An intuitive interface without complex add-ons allows you to properly master the work in this program in as soon as possible. In terms of visualization, the application is on par with competing applications. It is worth noting the realism of the picture.

Professionals will be interested in the possibility of creating custom libraries of materials, elements and furniture.

Great convenience and functionality characterize the calculations and reports of the application. In particular, using adjusted prices for furniture parts and materials, you can calculate the total cost finished project, as well as the total costs of individual components.

Pro 100 also allows you to create and edit materials with greater convenience. A photograph, drawing or scan of the target material will be processed using the program, and the user will only need to indicate the actual dimensions.

Furniture project in Pro100 program

Furniture project in Pro100 program Disadvantages of the Pro100 program

The main disadvantage is the rather high cost of the software, which, in principle, is lower than that of competing products, but not by much. You can download it for free and try the demo version of the program to see if it’s right for your job or not.

At the same time, the decision to save money by using the demo version will be overshadowed by the inability to print or export your project. The demo version does not even allow you to simply save the developed project.

If a specialist is seriously involved in furniture design, then Pro100 is worth the money. This easy-to-learn program allows designers to fully realize their creative potential.

Anyone who has at least once designed and created cabinet furniture on their own will no longer visit furniture showrooms. In this simple matter, it all starts with a design that describes the product in great detail. Today we will talk about the most common programs for designing cabinet furniture.

Design challenges and complexity assessment

Designing cabinet furniture is a rather meticulous task, requiring attention to both the global concept and many small details. Unlike drawing on paper, CAD tools give you control over all created objects, even those that are hidden from view by other details.

The main design task, which consists in the spatial arrangement of cabinet furniture parts and the arrangement of their larger groups, is solved by almost any furniture program. The three-dimensional visualization function allows you to freely manipulate objects, move them in space and view them from any advantageous angle.

But the specifics of working specifically with furniture components are not implemented in every software. The PRO100 program, for example, despite its simplicity, speed and good visualization system, does not see at all the functional difference between a housing part or door handle. In the context of PRO100 or bCAD, any object has a shape, location, color or texture, but its purpose is modestly silent.

bCAD

bCAD

This slows down work on large projects. For example, in the BAZIS complex the processes of arranging fittings are automated; the program can automatically generate sets of hinges, handles or extension systems and place them in accordance with the installation rules, simultaneously generating a marking diagram for drilling. And this is only one module of the program called “Furniture Maker”, designed for modeling, and there are half a dozen other parts of the complex - for cutting sheets, organizing storage, production and sale of furniture.

It is the ability to work with specific furniture design tasks, and not just put boards into a general structure, that distinguishes specialized software from amateur software. The PRO100 program costs about $1000 fully equipped, and it has a demo version that is quite suitable for creating your own amateur projects. The BAZIS complex is the main competitor of PRO100 on the Russian market: it costs half as much, has twice as many capabilities, but the visualization system is lame.

Programs for 3D modeling

The need to visualize the working scene is mainly needed for the presentation of furniture and the development of catalogs. When designing furniture yourself, this fades into the background, although it can serve as a useful addition. The design process optimally takes place in programs like PRO100, KitchenDraw or WOODY - one of the few free, but somewhat outdated programs today. They have a function for quickly switching the displayed view, from a black and white sketch to a three-dimensional scene with its own light sources.

Three-dimensional model in WOODY 2.0

Three-dimensional model in WOODY 2.0

In the “BASIS” complex, for example, everything is not so rosy: the main work is carried out in the “Furniture Maker” module, and the construction of a visual concept, playing with colors, shadows and textures is moved to the “Salon” module, which is purchased separately. It cannot be argued that the possibility of visual assessment makes designing fun, but in professional activities it is rather a distraction.

Despite the availability of graphical tools, almost all work is carried out using parameterization methods. An object on the screen is just a display; it has a number of properties and features that are set manually through a parametric window. True, in a purely visual mode, you can quickly sort through the existing library of furniture, select the samples you like, quickly change the size and proportions (stretch, compress) of each individual product and make a global arrangement, and only then move on to working on the details.

Features of hand-crafted details

We have already said that some programs have tools for automating the placement of elements and working with individual parts, but this is only one side of the issue. Each program has a number of primitives - objects from which the assembly of more complex parts and groups always begins. In PRO100 and Astra, for example, the base object is a board, vertical or horizontal. It is possible to edit the plan form, but only once, so all project details will have a constant section along at least one axis. In practice, this results in difficulties when modeling radius facades, plinths and countertops.

In KitchenDraw, bCAD, WOODY and BAZIS, objects are also created using board primitives, but there are more tools for working with them. For example, boards can be of several types, such as bottom, back wall, side wall. Guided by the global properties of the project, the program can determine their more specific aspects, such as size, position, connection to other parts, or provide for some actions that can be performed on an object of this type.

bCAD

bCAD

Professional software can be equipped with a template engine that offers standard designs for drawers, compartments, doors, countertops and other common furniture elements. Another difference between professional software is the ability to work out fasteners. In the Astra program, an analogue of the BAZIS complex both in functionality and cost, it is possible to mark drilling and milling locations on parts for the installation of canopies. But BAZIS-Mebelshchik creates comprehensive additive and edging maps, compiled, like all exported BAZIS documentation, in accordance with ESKD or ISO.

Visualization differences

CAD systems for designing cabinet furniture have three basic display modes. First - wireframe view— common to all programs; in this mode, only edges and vertices of parts are displayed. Modeling furniture components, seeing only their frame, turns out quite quickly, but when large quantities details, a jumble of lines causes confusion.

Then the translucent display mode comes into play, which shows completely or partially lines that are not visible from the current angle. The mode is good for composing small composite objects into even larger ones and relative positioning.

The third mode, inherent in almost all CAD systems, is the overlay of colors and simplified textures for a visual assessment of the success of the layout and relationships color range, sizes and shapes. But here, too, there are nuances: in programs with the simplest visualization, for example, PRO100, there is no possibility of applying textures and colors to individual edges of parts. Therefore, displaying contrasting edges is not possible unless you create the edge as a separate object with its own texture.

The creators of KitchenDraw went further and added rendering capabilities. By by and large, no CAD software for cabinet furniture will provide such display quality, except perhaps non-specialized CAD programs. But is such an opportunity justified at an hourly cost of the program of $2-3 or a subscription for a year for more than $500? However, KitchenDraw gives you 20 free hours, which is enough to familiarize yourself with the program and create a couple of trial projects.

Libraries

There is perhaps no more valuable factor than the vastness and content of the component libraries for the program being used. Majority furniture showrooms They usually work from a very impressive catalog of furniture products and sets, only adjusting their sizes to the customer’s premises. Who is stopping you from doing the same?

Even the simplest PRO100 program enjoys unprecedented success among furniture makers, largely due to the most extensive library with the ability to freely import third-party projects made by other craftsmen. All you have to do is add some technical details, adjust the location of shelves and drawers, color - and the finished detailing will be in your hands in 30-40 minutes of work.

Libraries may include both ready-made headsets and even entire interior concepts, as well as individual furniture sections. Additionally, any library includes samples of paint and texture palettes in accordance with generally accepted standardization, so questions about the correct color selection when ordering cutting usually do not arise.

Cutting programs

Having a sheet cutting optimization module in the program can be very useful. Of course, when ordering sheet cutting, just a list of parts is enough. But, having thought through the cutting scheme, you will be able to estimate the final cost of the furniture or visually display the edging, drilling and milling maps on a printout.

Of course, free import of projects provides increased speed and ease of operation, so the purchase of additional modules for the BAZIS or Astra systems is beneficial mainly for furniture manufacturers. On an individual basis, you can also use free third-party programs such as Cutting.

Of course, it will take some time to enter the detailing parameters manually, but for one-time use this is quite enough.